The True Cost of Steel Detailing: Why Cutting Corners Can Derail Your Project

If you’ve ever been told, “I’m not doing this for free,” you can likely empathize. As a steel detailer, I’ve heard these words far too often, and it reflects a larger issue in our industry. Steel detailing is an incredibly competitive field, with labor costs differing drastically from one country to another. This creates a situation where some firms can absorb the costs of “doing it twice” better than others. But regardless of whether you’re based in India, Australia, New York, or Wyoming, detailers’ incomes are based on the number of hours worked and ensuring that those hours stay within the initial bid estimate—similar to how architects and engineers are compensated for their designs.

So why does the industry expect steel detailers to work overtime, often under unrealistic deadlines, and without adequate compensation for the added work caused by last-minute changes and incomplete information? How does this lack of consideration not only affect the steel contract but also the entire construction project?

What Does Steel Detailing Actually Cost?

Steel detailing typically makes up 6% to 10% of the total steel contract cost in commercial projects. As a vice president from a large California fabricator once put it, “Detailing is 10% of my cost, but 100% of my destiny.”

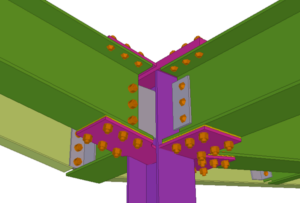

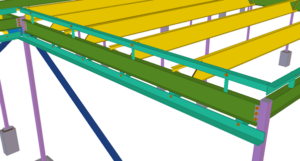

Steel detailing is integral to every stage of steel design, procurement, fabrication, and construction. It involves creating precise instructions and organizing all structural steel components to eliminate waste, boost productivity, and minimize costs in both the shop and the field. Spending an extra dollar on detailing could save up to nine dollars downstream on the project.

When detailers bid on a project, they base their pricing on the assumption of a smooth workflow, with minimal changes or delays. A smart detailing manager once told me, “I have to bid assuming I can do everything once—if I didn’t, I’d never win the job.” But the reality is that incomplete designs or last-minute revisions often disrupt this workflow, causing delays, rising costs, and forcing detailers to ask for change orders just to recover. Without those change orders, corners get cut, which introduces significant risks to the project’s schedule and costs.

Why Risk Cutting Costs on Such an Essential Service?

Steel fabrication, much like detailing, is a highly competitive market, and even a 5% saving can make a huge difference when bidding for jobs. Some fabricators intentionally lowball detailing costs to win a bid, knowing that they will have to absorb the costs of inevitable late changes. Meanwhile, project managers may seek out ways to cut costs, seeing detailing as an overhead cost they can control, especially when it comes to reducing what is seen as a variable expense.

However, the problem with undervaluing detailing is that it can shift a detailer’s focus from building a risk-free project to just getting the job done as quickly as possible. This comes at the expense of quality and accuracy, which can lead to serious problems down the line. Here’s what happens when detailers are forced to rush or cut corners:

- Field issues arise when connections and assemblies aren’t checked for proper fit.

- Late RFIs are missed, potentially delaying approval and fabrication timelines.

- Quality checks get skipped, leading to issues like incorrect welds, misaligned profiles, and missed details that could have saved time and materials.

- Field vs. shop welding issues result in unexpected costs due to miscommunication.

- Sequencing errors in piece markings lead to materials being sent out of order.

- Late change orders become frequent as detailers try to recoup lost costs, leading to project friction.

At the core of the issue is the idea that detailers are supposed to focus on designing how the steel will be built—this is the value they provide. Yet, when pressed to work faster or under pressure, they stop thinking about the overall build and simply churn out designs without addressing potential issues. I’ve even had managers tell me, “Don’t worry about that, they’ll figure it out in the field.”

The Solution: Value Your Detailers

The solution isn’t simply to throw more money at detailing and expect things to improve automatically. There’s plenty of poor-quality detailing out there, and it’s crucial to vet and select experienced, skilled detailers. Rather than always focusing on finding the cheapest subcontractor, look for partners who add value and understand the process. If changes or missing information disrupt a detailer’s workflow, ensure they are fairly compensated for the additional work required. Likewise, try to budget extra funds for when necessary changes will inevitably occur during the project.

The key takeaway is understanding how detailers operate and the impact late changes or information gaps have on their work. If you, as a fabricator or contractor, understand this, you can manage the risks more effectively.

2D vs. 3D Detailing: Why the Difference Matters

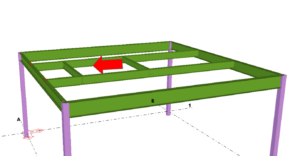

Today, most detailers use 3D modeling software, a significant departure from the traditional 2D drafting approach. In 2D, each drawing was largely independent of the others, so late changes had a more localized impact. However, in 3D detailing, everything is interconnected. Changes to one part of the design ripple throughout the entire model, impacting numerous components.

In 3D, detailing is more like an assembly line: each step depends on the previous one, and any changes create a cascading effect on time and cost. Fabricators benefit greatly from the added value of 3D detailing without paying more, but detailers are stuck with the added time and cost when late information or changes disrupt the model.

This is why many detailers include clauses like, “Priced based on a single pass, undisrupted workflow” in their contracts.

The Ripple Effect of Late Information and Design Changes

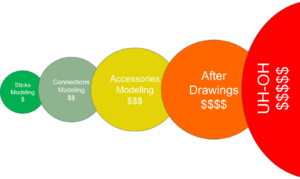

Imagine a base unit of 1, which represents the simplest form of a task for the detailer. When changes occur, the level of impact increases significantly as the project progresses. Let’s look at this in stages:

- Preliminary Modeling (1x): This is the fastest stage. Simple framing changes or minor RFIs can usually be handled without additional cost, but frequent updates can still lead to inefficiencies and extra charges.

- Connections (2x+): Changes here, especially to more complex elements like skewed or moment connections, have a greater impact and will likely incur additional charges.

- Accessories (3x+): Architectural and safety features, which require detailed cross-trade coordination, are costly and time-consuming to model. Changes to these items will almost always result in additional fees.

- Drawing Finalization (4x): Once drawings are finalized, any changes require significant effort to update the model and drawings, leading to major cost increases.

- After Approval (5x): Once the drawings are approved, any changes result in substantial rework. This can be one of the most costly stages for a detailer, as even minor revisions can disrupt the entire process.

Managing Costs and Expectations

A smart strategy is to understand the full impact of changes before the project begins. If a project is expected to have significant changes or complex framing, discuss with the detailer early on about how to handle these complexities. This proactive approach can help mitigate additional costs, such as re-mobilization or the need for separate work phases.

In Conclusion, while detailing may only account for a small percentage of the overall steel contract cost, it holds immense power in determining the success of the entire project. Cutting costs on detailing to win a bid may seem like a quick fix, but the long-term consequences of such decisions can be significant. Understanding the detailing process and the challenges faced by detailers can lead to better collaboration, fewer surprises, and a more successful project overall.