Having durable, practical, and attractive spaces in a shop is greatly helped by the fit-out steel fabrication process. Being a major economic centre, Melbourne offers business owners special opportunities to upgrade their stores with styles custom-made from steel. If you are either starting or remodelling a shop, knowledge of steel fabrication can improve your commercial space a great deal.

Why Steel is important for Shop Fitouts

Technicians modify raw metal into useful systems that fit in retail shops. You cut, bend, join, and weld the metal to shape custom systems and structures for many types of packages. The usual store fit-out items you find are shelving, racks, counters, show devices, stairways, and decorative panels.

Properly built metal structures are suitable for retail settings since they are powerful, flexible, and look memorable.

Why Choose Steel Fabrication for Your Shop Fitout?

Strength and Durability

Since steel is greatly resilient and can endure much strain, it keeps its shape when used heavily. Steel shelves, counters, and displays are perfect for retail stores as they stay practical and attractive for years, even when lots of people use them. Wooden or plastic ones are more likely to get damaged, while steel ones stay undamaged for a long time.

Customisation

Steel fabrication gives companies the ability to customise their products. All shops are different and may need a unique store design. Steel can be made into any shape, size, or style. You can work with steel to get any kind of form you are looking for, whether you prefer modern smooth lines or more artistic designs.

Cost-Effectiveness Over Time

While initial costs may appear higher compared to some other materials, steel fabrication often proves more cost-effective in the long term. Because steel is strong and only needs little care, companies can save money in the future. Mould, insects, and moisture do not harm it, which also makes it valuable to retailers.

Important Stages of Shop Fitout Steel Fabrication

The process of creating designs and organising plans

First, detailed planning and design must be done before fabrication can start. During this stage, fabricators join hands with business owners and designers to decide on all requirements, measure everything properly, and make careful plans.

Material Selection

Choosing the right sort of steel is critical. Depending on the desired electricity, finish, and use, fabricators pick out suitable steel grades and thicknesses. Materials along with chrome steel, light metal, or galvanised steel offer one-of-a-kind benefits and aesthetics.

Cutting and Shaping

Once plans are permitted, steel sheets or bars are cut and shaped using specialised tools and machinery like laser cutters, plasma cutters, and CNC machines. This guarantees accuracy and consistency in every piece fabricated.

Welding and Assembly

After cutting and shaping, person components are welded and assembled. Expert welders carefully piece together metal elements, making sure structural integrity, stability, and alignment with layout specs.

Finishing and Installation

The very last step includes completing strategies like sprucing, portraying, powder coating, or galvanising to decorate the look and shield against corrosion. Once finished, the custom steel structures are set up professionally, ensuring a steady and particular fit in the store.

Benefits of Professional Steel Fabrication

Employing professional fabricators ensures quality and reliability throughout the project. Professionals possess the skills, tools, and experience necessary to execute complex designs with precision. They can manage every phase, from design to installation, helping businesses avoid costly errors or delays. Furthermore, expert fabricators provide insights and recommendations, helping retailers achieve optimal results and maximise their investment.

Customised Solutions

Recognising that every project is unique, we offer bespoke designs that reflect your individual style and meet your specific functional requirements.

Commitment to Quality and Safety

We adhere to the highest industry standards, ensuring that our staircases are not only visually striking but also structurally sound and safe.

Client-Centric Approach

Your satisfaction is our priority. We maintain open communication throughout the project, ensuring that your expectations are not only met but exceeded.

Common Applications in Retail Shops

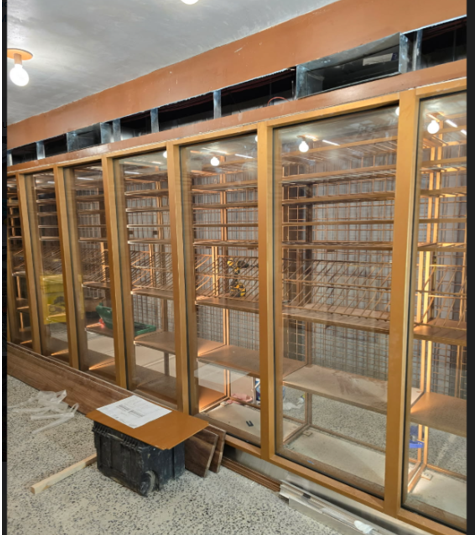

Display Units and Shelving

Steel fabrication is regularly used to create customised show gadgets and shelving, improving product visibility and keeping aesthetics. Sturdy and visually attractive shows can substantially raise client engagement.

Counters and Cashier Areas

Steel counters offer durability and elegance, critical for busy cashier regions that revel in constant utilisation. These surfaces are resistant to scratches, dents, and other damages commonplace in retail environments.

Staircases and Railings

Custom steel staircases and railings not only provide necessary safety but also add visual interest, complementing the overall interior design. With endless design possibilities, steel allows businesses to create distinctive architectural features.

Conclusion

Shop fit-out steel fabrication is an effective solution for businesses aiming to create long-lasting and Long-lasting and visually appealing retail spaces can be created in businesses with the help of shop fit-out steel fabrication. Austeel Australia Pty designs and provides steel fabrication services that help improve your shop’s performance and attractiveness. Deciding on steel lets you achieve strong and flexible results for your retail space that last you many years. From designing the gate to installing it, all the steps are carried out by qualified professionals looking for perfection. Steel fabrication gives a good value for money because it helps reduce costs and upkeep over time. Melbourne businesses benefit from steel fabrication since it helps them meet their customers’ requirements and mark their position in a crowded trade.

Read More:

From Residential to Industrial: Tailored Steel Solutions Across Melbourne

Steel Fabrication & Installation in Melbourne: A Complete Project Guide