At Austeel Australia Pty. Ltd., our clients are the main focus of everything we do. We work on personalised solutions that reflect your unique needs. Our transparent, integrity-driven approach is key to our success.

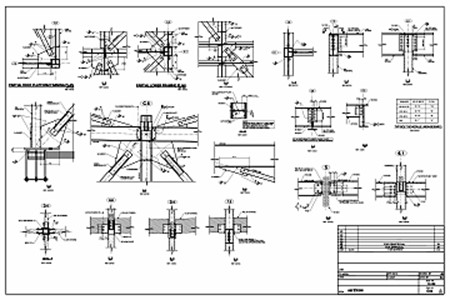

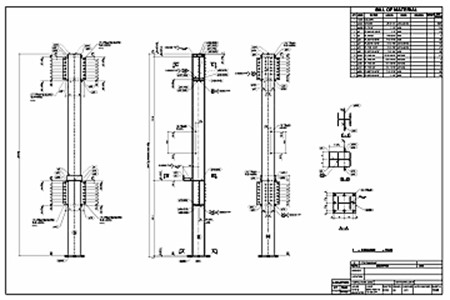

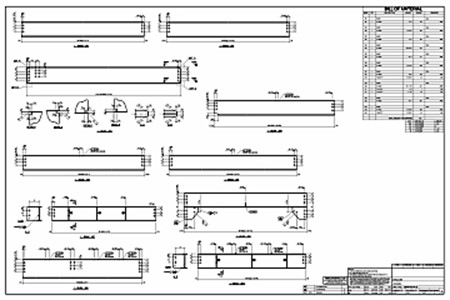

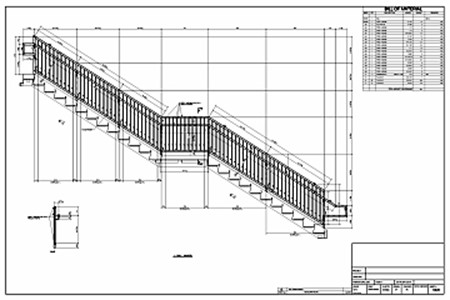

In steel detailing, the detailer’s drawings covering the making of these steel pieces are called shop drawings. They identify the precise specifications for fabricating each member/piece of a structure.

The steel fabricator uses these drawings, (also called detail drawings) to produce these members. With steel detailing, comprehensive shop drawings may include for each piece:

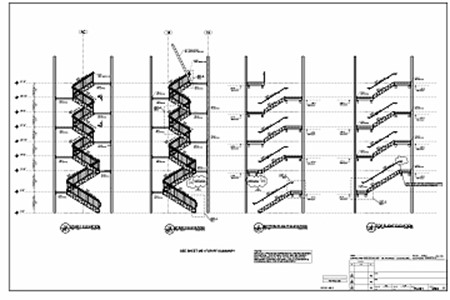

With steel detailing, once the steel fabricator produces the steel members, the steel detailer steps in again and produces the drawings for the erection of the steel members in the field. These are called erection drawings.

It is the construction site steel erector who refers to these drawings in the steel detailing process, in order to know how and where to build with the fabricated steel pieces. Included in the erection drawings are dimensional plans to identify the steel members, in addition to all work required on the site including welding, bolting, and installing masonry anchors.

For the detailer in the steel detailing process:

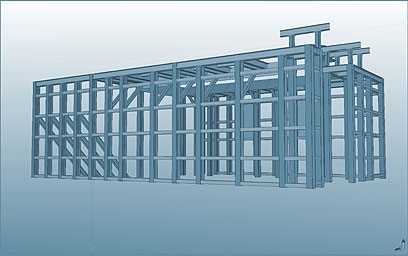

Computer-aided drafting (CAD) has replaced manual drafting for the most part in steel detailing. The detailer using these systems generate his drawings on the computer, employing software designed for this purpose, and then prints them. Accordingly, in the skills needed for steel detailing, the detailer needs proficiencies in the use of computers and comprehension of the particular CAD software he will utilize.

Steel detailers add another category for those working with 3-D modeling applications. The process for the construction of these drawings is very different from two-dimensional drafting. In this case, the project is built in 3-D before production of shop drawings from the model.

The steel detailer has an extremely critical role in the steel detailing process. He links to the structural engineer, the architect, general contractors, the steel fabricator, the steel erector, the checker, relevant people in the CAD and CNC computer processes, and more. In the flow of steel detailing, the detailer’s shop and erection drawings are crucial to the entire process.

Contact Us on 1300 589 166 or one of our sales team representatives so we may provide you with complete samples on some of our previous projects.

Austeel Australia PTY Ltd steel detailing & structural steel services has an excellent track record for providing impeccably accurate details in a timely manner. We will not hesitate to provide you with actual sample projects. We can also provide you with references from some of our current customers.

Choose Austeel Australia Pty Ltd for quality steel construction and fabrication solutions.